Zastava AKs, Part 2. M70 – The First Mass-Produced Yugoslavian Kalashnikov

In part 1 of this article, I wrote about the early history of Zastava AKs: M64 and M64A. Right now, the only place where you can find a real M64 is the Zastava Arms Museum in Serbia. In this article we’ll talk about the first mass-produced Zastava AKs, the M70.

AK History @ TFB:

Often, dealers and even some collectors in the US would use the designation “M64” to describe early Zastava AKs, but that is simply incorrect. M64 was merely a prototype, and if you can find one outside of a Zastava museum – let me know, I really need good pictures of it.

Unlike the Soviets, who didn’t even have specific names for Type 1, Type 2, and Type 3 AK variants, the Yugoslavian army was meticulous when it came to designations of different variants of Yugoslav AKs. In the 1985 repair manual for Zastava AKs, the first chapter is called “Identification of Automatic Weapons” and goes into so many details you can use this chapter as a collector’s guide.

Page from 1985 repair manual

The first mass-produced Zastava AKs were called M70, they had milled receivers and screwed-in barrels. The naming system remained unchanged since M64. Standard M70 had a wooden stock, while the M70A had an under-folding stock. There was also an M70A1 that had a side mount for night scopes.

These rifles are pretty hard to find, but I came across one a few years ago in Baghdad. It looked a little rough but worked flawlessly. With this rifle, I first noticed that the milled receiver of Zastavav AKs was very different from the milled receivers of Soviet AKs.

M70A, the earliest mass-produced Yugoslavian AK

The lightning cut was only on the right side, and the left side had its own unique shape. Also, on the left side, you could see a pin that you never find on any other AK variant.

This pin is supposed to retain a fully functional bolt catch – a unique feature of early Zastava AKs. The rifle with a bolt catch only works with modified AK magazines that have a special cutout in the front of the left lip. A functioning bolt catch is one feature most AK manufacturers can’t offer to this day.

However, Yugoslavian military leadership decided they wanted their service rifle to use standard AK magazines, and the bolt catch lever was removed from all M70s, leaving a pin on the left side as a reminder of the ingenuity of Zastava engineers.

M70A receiver with unique bolt catch pin that was not present on other Zastava AKs

Later on, Yugoslavian engineers standardized one more thing – the barrel attachment method. While the first Soviet AKs had screwed-in barrels, after 1959 barrels were pressed in and pinned. This technology requires less precision in barrel manufacturing and the next generation of Zastava AKs had milled receivers and pinned barrels.

This variant received a new designation – M70B for the standard rifle with wooden stock and M70AB for the folding stock version. These rifles are still somewhat rare, so I was blown away when I came across an entire arsenal of those rifles in the armory of one African SWAT unit I worked with.

All those rifles had Ultimak rail systems installed and most were used with Aimpoint red dot sights. These rifles have seen some stuff. One AK in particular had several bullet holes. One bullet got stuck in the rail, and another one ripped through the receiver, destroying a part of the trigger mechanism. The officer who used it died in a firefight with terrorists, and the rifle remains in the unit.

M70B with UktiMak rail. Note the bullet hole next to the trigger guard.

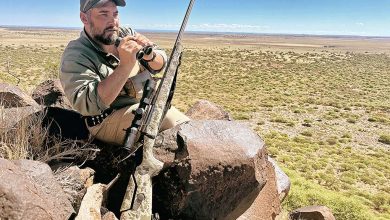

I was tasked with inspecting and evaluating those rifles. After the inspection, I knew we would have a memorable range trip.

The rifles were at least 50 years old, but functioned flawlessly – not a single stoppage. However, I couldn’t hit a target even at 10 yards. Every rifle that failed my bore gauge test was keyholing, spraying bullets all over the target stand.

Why did it happen? Zastava AKs initially did not have chrome-lined barrels. That was not a problem for Yugoslavian soldiers, who cleaned their rifles at every opportunity, but in other countries the bore condition of Zastava AKs often became catastrophic. Only in 2020, did the Zastava factory begin to chrome-plate all of their barrels, solving this problem once and for all.

M70B used by a SWAT team in an African country

After my range trip, I suggested that the owner of the rifles should procure new barrels because the condition of the weapons was remarkable: nice and smooth action, no significant wear on working parts, and even the finish did not peel away after all those years. I hope one day I will come back to this project and finally replace those barrels.

In my experience, the lack of chrome lining was the only issue. Zastava factory always used high-quality Slovenian steel. I learned it the hard way – in Afghanistan, we used to counterbore worn-out barrels, drilling out the first inch of damaged rifling. We did it on Soviet, Romanian, Hungarian, and Chinese AKs but when we tried to do it on Yugoslavian AK our standard drill just couldn’t cut the steel of the barrel. We were shocked and turned it off before it overheated.

In the next part of the article, I will talk about the history and my experiences with the most common Yugoslavian AKs.